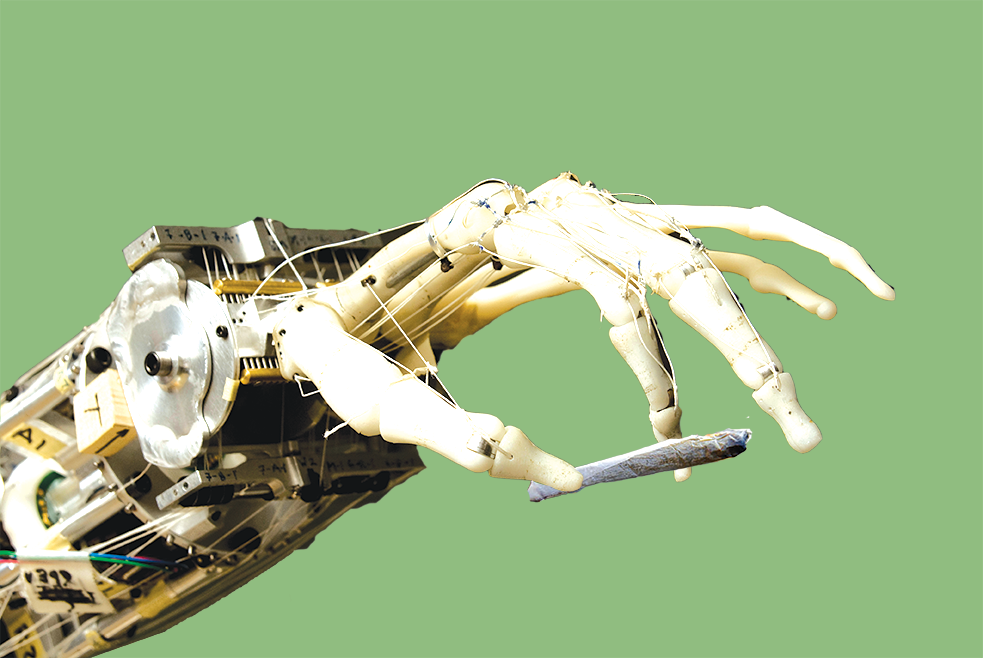

With all the buzz about Artificial Intelligence in the news these days, I decided to explore the latest in robotic cultivation of cannabis. AI is creeping into – some say taking over – fundamental components of our lives.

If this is the case, then why not grow cannabis using AI that guides robots and automates the process of going from seed to sinsemilla?

My first job was to find out if robotic production of a cannabis crop is even possible. After a couple of hours noodling around the internet, the short answer to this question is: Yes, robots can be used to grow weed. However, the long answer is: It’s complicated, and it depends.

The central concept in understanding how robotic cultivation can create high-quality cannabis is scale. Scale is a concept hiding in plain sight. Once you understand how scale drives our understanding of the natural world, you can never dismiss it.

Currently, the robotic cultivation of cannabis has the potential to work quite well for a consumer who wants to grow a personal stash of a few ounces of high-quality buds in the comfort of their own home over 10 to 15 weeks. There are several brands of personal grow closets that are commercially available. For about $1,500 to $2,500, these robotic hydroponic units can make cannabis production happen with little effort on the grower’s part.

These automated cannabis grow boxes are about five feet tall, two feet wide, and two feet deep, or about 20 cubic feet in volume. They are connected to the vendor’s Wi-Fi network that drives the algorithms and computers that regulate critical grow parameters such as the timing of light and dark, watering, fertilizer and nutrient levels, pH levels, oxygen and carbon dioxide levels, etc.

The automated units have video cameras that monitor plant growth, the presence of disease and pathogens, and when the flower buds are ready to be dried and harvested. One vendor claims that with their unit, the end-user needs to spend only about two minutes per day monitoring the progress of the grow.

The personal cannabis grow units are remarkably energy efficient. They use the same amount of electricity as a 150-watt light bulb. Many have child-proof locks, and some claim to have an activated charcoal filter to keep your house from smelling like, well, a weed factory. There is a high-end robotic cannabis grow unit from Green Goddess Supply called “The Armoire,” because it looks like a piece of heirloom furniture. No joke.

Assuming it costs about $250 an ounce for good quality flower, and a three-ounce harvest from the cannabis plant in the grow box, the weed-growing robot should be able to pay for itself after three or four harvests. At least that is what the people selling these units claim, and this seems like a reasonable claim, assuming that the small-scale grow is successful in both desired quantity and quality.

So, yes, it is clear robots can grow cannabis, at least at a small, single person use scale. Scaling up a personal robotic cannabis grow operation to a commercial level is where things get complicated. To get some perspective about whether the personal robotic cannabis growing technology can be scaled up to commercial production I asked Dr. Eric Rosen, a research scientist at Boston Dynamics AI Institute who is an expert on robotic systems, for his perspective. Rosen replied, “Whereas we currently now have ‘fully-automated’ solutions to personal-level robot cannabis production… I could see it being quite some time ’til we have ‘fully-automated’ solutions to commercial-level cannabis production.” Dr. Rosen elaborated that “controlling and monitoring the state of the environment in a commercial-scale process, so as to enable full automation of the production process, is extremely costly and challenging, to the point that fully-automated solutions are not practical or effective, yet.”

This is where things get complicated and land in the “it depends” territory. Most fully automated cannabis growth depends on how progress in AI and robotics advances over time, and how much time such progress takes. Dr. Rosen noted “AI and robots will help in scaling commercial-level cannabis production in the near future.”

I asked Dr. Rosen if there are other robotic or AI production systems that he knows about where they started with n = 1 thing (e.g., a one-plant cannabis grow over a defined period) and through a series of iterations morphed to where n = 100 things (e.g., a 100-plant cannabis grow over a defined period), and he replied, “Yes, this is exactly how fleet-based robots work. In fleet-based robots, you can buy from one up to n robots, and they will automatically coordinate and parallelize work to achieve some goal. If you want, at any time, you can just buy more robots (m), and now you have n + m robots aiding in this process.”

The idea that commercial cannabis grows can be run by robots is indeed complicated. But it is theoretically possible, based on what we know about the state-of-the art technology gained from innovations in personal-scale cannabis grows.

Dr. Rosen finished his comments on the topic of robotic cannabis growing with a perspective that is too often overlooked in most media coverage of AI and robotics in our lives. He noted that “robots and AI technology are not replacing human teams, they are adding to it and supplementing them, acting as tools to enhance their productivity.”

Whether it is managing the moving parts in an automated cannabis grow, or managing moving inventory in an automated warehouse, the human factor – and improving the human condition – is essential to any successful application of AI and robotics. Even when it comes to growing weed.

Lenny Brennan is a Rhode Island native who recently returned to the Ocean State after a 45-year career as a wildlife research scientist and professor.